Ideal Practices for Picking the Right Anti-Foam Control Service for Your Needs

Selecting a reliable anti-foam control option demands an extensive assessment of your distinct functional requirements. Secret factors to consider consist of the particular homes of your process, such as chemical, ph, and temperature level interactions, every one of which considerably affect the performance of defoaming representatives. Making certain compatibility with the tool and adhering to regulative criteria are crucial for effective execution. As we check out these crucial variables, it becomes obvious that the ideal selections can result in not only instant benefits but additionally lasting operational renovations that necessitate more examination.

Understand Your Foam Problem

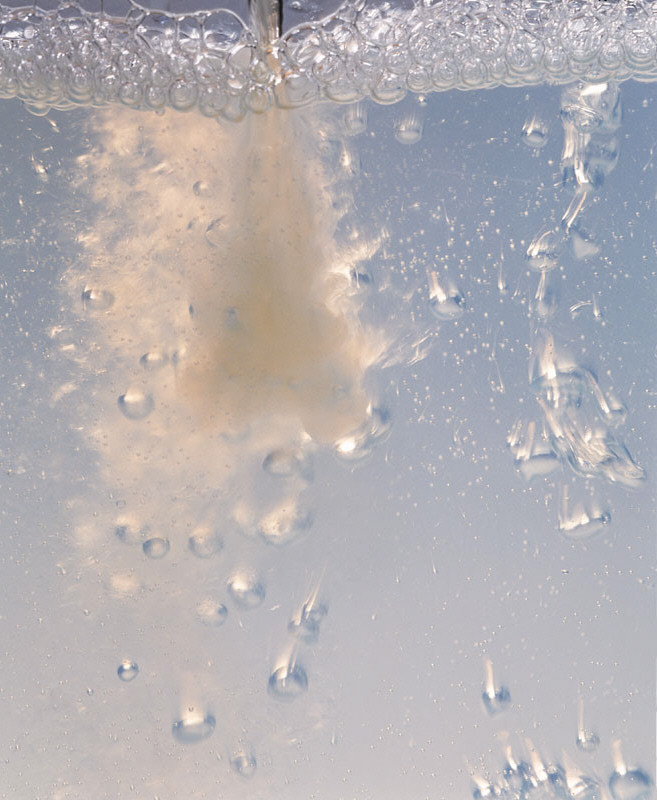

Often, companies experience foam-related issues that can impede operational efficiency and product top quality. Foam formation can take place during different processes, including blending, fermenting, and transportation, and it frequently causes equipment ineffectiveness, manufacturing downtime, and raised functional costs. Understanding the underlying reasons of foam generation is essential for resolving the problem effectively.

Foam can arise from several variables, such as the nature of the products included, frustration degrees, temperature level variants, and chain reactions. Particular surfactants can exacerbate lathering, while high shear blending can present air, leading to unwanted foam accumulation. In addition, environmental problems and the certain attributes of the liquid systems being used can significantly influence foam actions.

By evaluating these variables, organizations can get understandings into their foam problems, enabling them to create targeted strategies to alleviate foam formation and enhance total process efficiency. This foundational understanding is vital for selecting a suitable anti-foam control option customized to certain functional requirements.

Examine Anti-Foam Options

When thinking about anti-foam options, it is important to thoroughly evaluate the different solutions readily available on the marketplace to discover one of the most ideal solution for your certain foam-related obstacles. Anti-foam representatives can be found in diverse types, consisting of silicone-based, non-silicone, and natural formulations, each offering distinct residential or commercial properties and performance attributes.

Begin by analyzing the particular application demands, such as temperature thresholds, pH levels, and the kind of foam being produced. For circumstances, silicone-based agents are recognized for their performance in high-temperature environments, while non-silicone options may be better in food processing applications due to regulative considerations.

It is likewise important to consider the rate of application and the desired durability of the foam control. Some formulations might give immediate defoaming action, while others supply prolonged stability. Carrying out small-scale examinations can offer insights into the performance of each alternative in real-world conditions.

Take Into Consideration Application Compatibility

In the world of anti-foam solutions, making sure application compatibility is paramount for achieving optimum efficiency. The effectiveness of an anti-foam representative greatly depends on its capacity to work harmoniously within the particular criteria of your application, including temperature, pH, and the visibility of other chemicals. Different formulas may carry out variably throughout varied problems, hence extensive testing is necessary.

Begin by recognizing the features of your procedure, such as viscosity and the nature of the tool in which the anti-foam will certainly be used. Some anti-foam representatives might work well in liquid remedies yet fail in organic solvents. Furthermore, consider the potential interactions with existing components and products to prevent unfavorable results.

It is likewise crucial to evaluate the method of application. Whether the anti-foam is presented continually or batch-wise can affect its efficacy and longevity in the system. Guarantee that the selected item is not only suitable with the functional criteria however also straightens with any type of governing demands essential to your market.

Assess Environmental Impact

How does the environmental influence of an anti-foam control solution influence your general selection process? The eco-friendly impact of your chosen anti-foam agent is paramount, as it shows your commitment to sustainability and regulatory compliance. Picking a product with marginal environmental consequences can enhance your business picture and foster consumer depend on.

When analyzing ecological influence, consider the Discover More Here biodegradability of the anti-foam remedy. Biodegradable alternatives are usually more suitable, as they damage down much more swiftly and reduce lasting environmental damage. In addition, examine the capacity for bioaccumulation and poisoning to water life. Solutions with high poisoning can posture considerable threats to neighborhood ecological communities, possibly causing governing fines and ecological destruction.

An additional critical factor is the presence of harmful compounds. Anti-foams containing dangerous chemicals might require special delivery and disposal steps, complicating and boosting operational expenses compliance with environmental regulations. Therefore, choosing environment-friendly choices can minimize these risks.

Screen and Optimize Performance

To take full advantage of the effectiveness of blog here your anti-foam control solution, it is crucial to frequently monitor and optimize its performance. Constant analysis enables the identification of any type of deviations in foam degrees and the subsequent effectiveness of the anti-foam agent.

Carry out a methodical strategy to keep an eye on vital efficiency signs (KPIs), such as foam volume, stability, and the response time of the anti-foam representative. Use analytical devices and strategies, such as aesthetic inspections, foam height dimensions, and specialized sensors, to collect precise information.

In addition, preserve open communication with suppliers for technical support and insights on the current improvements in anti-foam technology. This positive method not only help in accomplishing optimal performance yet also lessens operational disruptions and enhances general process efficiency. Consistently taking another look at and fine-tuning your anti-foam method makes sure that you are successfully managing foam-related obstacles, eventually leading to improved performance and expense savings.

Conclusion

To conclude, picking the ideal anti-foam control remedy demands a comprehensive click over here now analysis of certain application requirements, consisting of temperature, pH levels, and chemical compatibility. Rigorous testing for instant and extended defoaming effectiveness is necessary, as is consideration of ecological effects and governing conformity. By prioritizing green choices and continuously checking performance, operational effectiveness can be enhanced while properly mitigating foam-related difficulties. Complying with these ideal techniques will help with educated decision-making in anti-foam control remedies.

Choosing an efficient anti-foam control solution necessitates a detailed analysis of your distinct functional demands.In the world of anti-foam remedies, making sure application compatibility is vital for accomplishing ideal efficiency.How does the environmental effect of an anti-foam control option influence your total choice procedure?In final thought, selecting the suitable anti-foam control service demands a comprehensive assessment of particular application demands, including temperature, pH degrees, and chemical compatibility (Anti-Foam Control Solutions). Sticking to these finest methods will help with enlightened decision-making in anti-foam control remedies